The latest slurry separation development from Bauer brings new ‘plug & play’ flexibility to slurry management for large farms and opens the way for contractors to provide separation services to smaller livestock units.

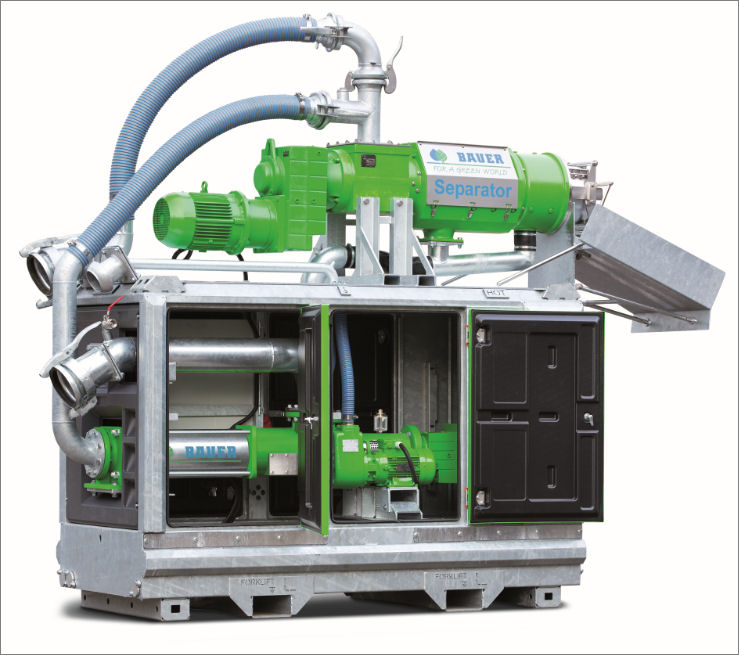

The remarkably compact unit comprises a galvanised steel frame housing a pump and enclosed control panel, with a screw press separator mounted on top with all the necessary pipework. Built-in pallet fork slots enable farmers and contractors to quickly off-load the unit from a trailer and pack it up again to move to a new location.

“It could be an ideal solution for the growing number of farms with more than one dairy unit and slurry storage and handling facilities,” says Adrian Tindall, UK & Ireland sales manager at Bauer. “For contractors, it offers a new service opportunity that will bring the benefits of separation to farms that cannot justify investment in their own system.”

The ‘plug & play’ unit requires minimal permanent infrastructure and is available with a choice of Bauer separators to provide different levels of output.

“The individual components are optimally integrated into the design for guaranteed stability and a long lifespan,” notes Hans-Peter Hojas, product manager at the Bauer Group. “It delivers a very high level of dry matter from slurry using a low amount of energy.”

All components are contained within and protected by a galvanised steel frame. They comprise a proven Bauer eccentric screw intake pump; a rotary discharge pump; an electronic control unit with cabling; and flexible intake, overflow and discharge piping with the famous Bauer quick coupling for easy connections.

Three versions are available: with the Bauer S655 or 655HD screw press separator, the mobile unit provides a typical throughput of 30cu m per hour and organic material up to 32% dry matter using a standard length screw with single screen.

The same dry matter performance is achieved with the S855 / 855HD separator but at throughputs of up to 40cu m per hour thanks to an extended screw and double screen. Both separators are powered by a 5.5kW electric motor.

For separation and the opportunity to produce a soft, comfortable bedding material for cow cubicles, the mobile unit can be equipped with the Green Bedding version of the 855 separator, which has a 7.5kW motor and achieves outputs typically of 25cu m per hour producing material with up to 36% dry matter for daily production and use.