Pumps made by Landia are playing a vital role in the success of a new 20 to 50kW anaerobic digestion plant at a 1,100 acre mixed farm in Hampshire.

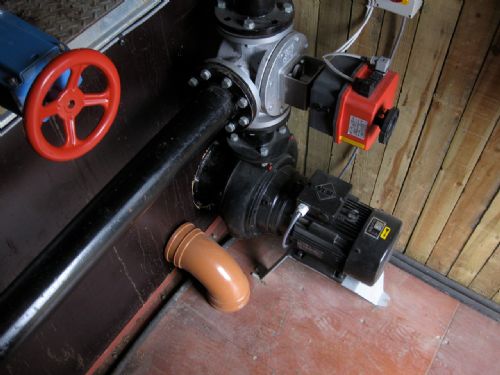

Designed to provide all the benefits of large scale AD, but simplified so as to be achievable on a farm scale, the £100,000 plant includes both long-shaft and dry-mounted Landia pumps, which handle slurry from the dairy and leftover fruit and vegetable waste from the arable side of the farm.

"We’ve done our level best to punish these Landia pumps with the thickest and most difficult materials we could thrown at them," said farm owner and Bioplex Technologies’ Director Chris Reynell, "but they just keep on working, even though there are no excess liquids because we’re very much a solids-in, solids-out operation".

’The Landia pumps have nearly halved the digestion time of the AD plant’

He added: "Landia had to meet our criteria for rugged and reliable equipment that could cope with heavy material such as silage, garden waste and horse manure, as well as slurry. We’ve had no problems whatsoever. The Landia pumps have nearly halved the digestion time of the AD plant and help produce a very healthy process. We have gained a significant upturn in biogas and benefitted from a superior compostable end-product, as well as enhanced fertilizer values. It’s a great piece of kit".

Reynell also explained that the outlay included a new reception tank and a Combined Heat and Power (CHP) generator that provides electricity for his farmhouse, with the excess to be sold. With the savings made from not having to buy artificial fertiliser and reduced fuel costs for the generator, he estimates a payback of 5 years.

He continued: "I’m sure that with all farms having different needs and many already having equipment on site, costs could be significantly lower than mine. To make the technology more accessible to farmers we broke the process into two stages".

• Firstly, the feedstock can be treated in a special first stage digester. The output is a pasteurized, compostable and spreadable material.

• Secondly, if energy generation is required, then a secondary stage digester is provided. These are modular, transportable – and built within containers.

Reynell says that the first process provides financial rewards by not having to buy-in artificial fertiliser. It also opens up the possibility of another revenue source by charging for waste collection from external sources. The second stage provides economic benefits too as the gas produced can be used in conjunction with bio-diesel to run a generator and produce electricity. Whichever method is chosen, he estimates that the system should be able to pay for itself after 5-10 years, particularly as fuel prices rise.

"To keep costs down and simplify the technology," says Reynell, "all the replaceable parts and fittings should be available from your local agricultural machinery dealer and can be installed and maintained by any qualified plumber and electrician. If you design your system to handle external waste sources, it can benefit the environment and the community by reducing the amount of material going to landfill and allows you to engage with local people in a mutually beneficial way."

Reynells claims that the digestate or compost element can also produce more direct environmental benefits, as it could be more efficient than many artificial fertilisers. This is because the nutrients and living organisms in the solid digestate are both slow-release (reducing watercourse pollution) and some are readily available for the plants, resulting in a quicker up take and a better yield. It has also been suggested that for every 1 ton of input into the system, 2 to 3 tonnes of CO2 is removed from the atmosphere, making AD ideal for organic and low input farming, because in addition to the natural fertiliser produced, the excess vegetation can be used again in the system.

"There are some issues with the longevity of anaerobic digestion systems, "says Reynell, "and you need to plan what you intend to put into the system, as the older type of digesters can easily block up in under five years due to grit and other heavy particles such as silica deposits forming mortar‟.

"There is also a major difficultly trying to get guidance on how we can connect anaerobic digestion derived electricity to the national grid at this level. I don’t think it would be particularly complicated, but no one seems to know quite who would do it or how much it might cost. Economically, anaerobic digestion as a technology still needs a simpler way to connect to the grid, perhaps higher electricity revenue e.g. from Feed-In Tariffs (FITs), particularly when compared to other renewable technologies.

The farmers I have spoken to are all very keen on the technology, particularly as we can tailor it to their needs while still being at a farm scale and relatively affordable."

"However, there is still some scepticism about the use of AD and I hope that as the new technology becomes more widely used, the true economic and environmental benefits of AD can be realised."