It's time for farmers to start thinking about the first cut silage - time to plan the detail, the target dry matter, chop length and additive selection, silage experts at BIO-SIL say.

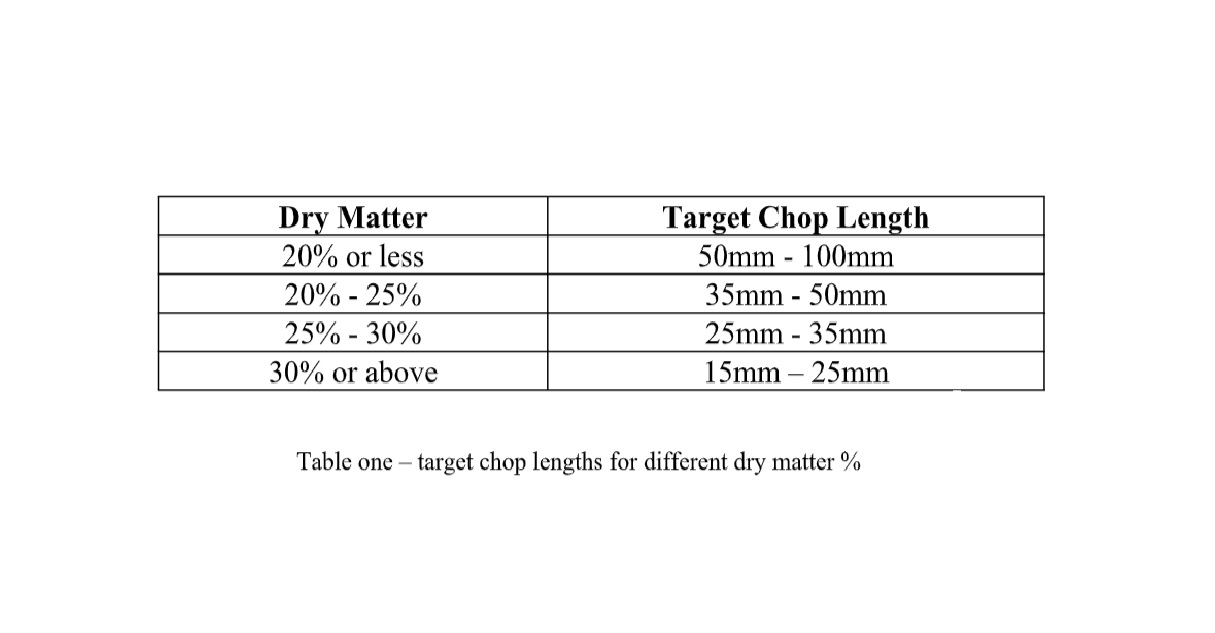

The dry matter achieved at harvest should dictate the chop length, the drier the silage the shorter it must be chopped to ensure good consolidation and good fermentation.

Longer chop lengths will increase the chances of aerobic instability and lead to massive increases in losses once the clamp is opened.

As with so many things, getting the dry matter right is a balancing act - on one hand, achieving high DM means leaving the mown grass for longer in the field, increasing the rain risk.

The cut grass is also respiring and burning up energy, and, unfortunately, getting silage in the clamp quickly doesn’t solve the problem of losses.

Low dry matter silage will produce higher losses in effluent run off, slower fermentation and a resultant reduced forage intake by cattle.

So how can farmers get a higher dry matter silage without the risks and losses?

Respiration losses will start as soon as the grass is mown - do not stop once the grass goes through the chopper.

The crop continues to lose value until a stable, lactic acid fermentation is achieved, so by choosing the right inoculant farmers can improve the silage dry matter and reduce losses.

This is because not all inoculants are equal and the test results prove it.

In Germany the DLG certification process tests most of the leading inoculants and none out perform BIO-SIL when it comes to rapid pH drop and stable silage fermentation.

Achieving a stable fermentation at around pH 3.8-4.0 in just 48hrs after ensiling, BIO-SIL outperforms most inoculants by 1 to 2 days.

This ability means high dry matter silage can be produced with no increase in losses.

BIO-SIL is also certified for use on forage with dry matters right up to 35% so there is no risk of using the wrong inoculant if farmers are blessed with an unexpected heat wave whilst the grass is on the ground.

Higher dry matter brings a risk of aerobic instability but there are practical actions that are by far the most effective solution to this.

Getting the chop length and the consolidation right at ensiling and then moving through the silage at 2m per week once the clamp is open will control aerobic instability.

Some additive producers tackle the issue by including acetic acid producing, hetero-fermentative bacteria or adding potassium sorbate that may aid aerobic stability, but this comes at a cost.

Whilst acetic acid and potassium sorbate can inhibit the growth of moulds and yeasts associated with silage exposed to oxygen.

High levels of acetic acid can make silage unpalatable to livestock reducing forage intakes.

Adding potassium sorbate also risks killing the very bacteria required for a good fermentation so needs to be added separately from the inoculant.

In trials BIO-SIL inoculant is proven to aid aerobic stability without resorting to these unwanted side effects.

This is because the pH drop is so fast that the yeast and mould populations don’t get a chance to become established in the initial fermentation of BIO-SIL® treated silage.

If you want to discuss how BIO-SIL can help you make high dry matter, low loss silage – contact info@bio-sil.co.uk.