Hypro welcomes news on air inclusion nozzle droplet sizes

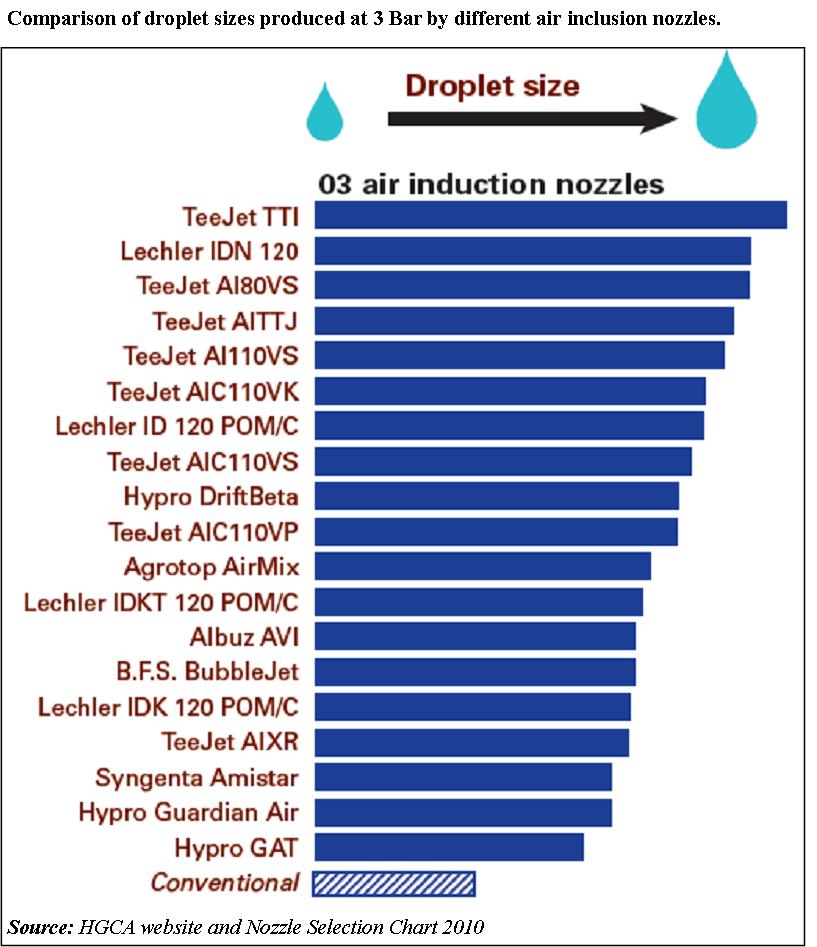

The publication by HGCA of a chart showing the droplet sizes produced by different flat fan air inclusion nozzles has been welcomed by Britain’s leading manufacturer of spraying equipment.

Hypro EU product manager Roger James says farmers and contractors can now make a more informed choice about which AI nozzles to buy and what crop treatment sprays to put through them.

"It has been known for some time that air inclusion nozzles of the same size but of different designs produce quite different spray droplet sizes," he points out. "But lack of independent data meant the details have never been published before."

Now, the HGCA cereals and oilseeds division of the Agriculture & Horticulture Development Board (AHDB) has produced a new Nozzle Selection Chart to give advice on the suitability of different nozzle types for different spraying operations and targets.

The previous edition merely categorised AI nozzles as ’finer’ and ’coarser’ but did not identify which ones fell into those categories.

"The new chart improves matters by identifying each nozzle and showing the size of droplet they produce at 3 bar pressure relative to a conventional flat fan tip," explains Roger James. "If operators want a nozzle that produces relatively small droplets suitable for a number of treatments – such as fungicides on cereals – they can see which AI nozzles will provide them."

The chart confirms Hypro’s claim for the GuardianAIR nozzle that, at typical operating pressures, it produces the smallest droplet size of any AI tip on sale.

Its performance is matched only by the Syngenta Amistar nozzle, which is produced by Hypro to the same design but with a different name, and the only nozzle on the chart producing smaller droplets is the GuardianAIR Twin. Identified on the chart as ’Hypro GAT’, this is a new nozzle undergoing final field evaluation this year before going on sale for the 2011 spraying season.

"The laboratory performance of the GuardianAIR Twin emphasises our productive investment in research and development, and our leading position in air inclusion nozzle design," says Roger James. "By further improving the air-liquid mixing process to produce a finer spray, and having rearward and forward facing outlets, the Twin will combine the best characteristics of current nozzle technology."

The significance of the small droplet size produced by both GuardianAIR tips relative to other AI nozzles is the potential for reliably applying a wide range of spray treatments and reducing the number of different nozzles a spray operator needs with him.

There will be around a third fewer droplets from a nozzle making droplets only 15% bigger than those from the GuardianAIR – this has clear implications for the delivery and retention of crop chemicals, especially to small targets. It would also make such a nozzle much less likely to be suitable for lower volume applications.

"In ideal conditions, a conventional flat fan like our Standard and Variable Pressure tips will still be the best choice for targets that need the finest spray," Mr James acknowledges. "But spraying conditions are rarely ideal; operators can use the versatility of the GuardianAIR to spray at normal pressures when conditions are good and then reduce pressure to increase droplet size for optimum drift control when spraying conditions are imperfect."

The HGCA Nozzle Selection Chart can be downloaded from the Crop Research - Spray Technology section of the HGCA.com website.