A high capacity venturi unit that sucks pesticides out of induction hoppers at a rapid rate during chemical loading has been developed by Pentair for the Hypro sprayer components range to further improve the operator’s experience when filling large crop sprayers.

The Hypro Eductor, which will be launched in the Sprays & Sprayers section of the Cereals Event, is a one-piece polypropylene unit that connects to the underside of an induction hopper and is plumbed into a water supply running to and from the sprayer tank.

“The Hypro Eductor includes a very powerful venturi that creates a vacuum in the top inlet so that the contents of the induction bowl are positively sucked away into the sprayer,” explains Hypro product manager Roger James. “It is highly efficient, drawing material out of the hopper at 150 litres per minute at less than 1 bar, a much lower pressure than similar units and one that puts less demand on sprayer plumbing.”

Unlike most similar devices, the Hypro unit also has the potential to reach 400 litres per minute at 4-5 bar pressure, which will help reduce filling times on big sprayers, especially when emptying large pesticide containers.

The characteristics of the new Hypro Eductor make it an ideal match for a centrifugal pump that also delivers high flow at low pressure.

Roger James is a keen advocate of using centrifugal pumps on crop sprayers because of their simplicity and low maintenance demand. Also, he points out, they are capable of delivering an exceptional flow performance from a small, light-weight unit, which has advantages for installation on the sprayer – and all at lower cost.

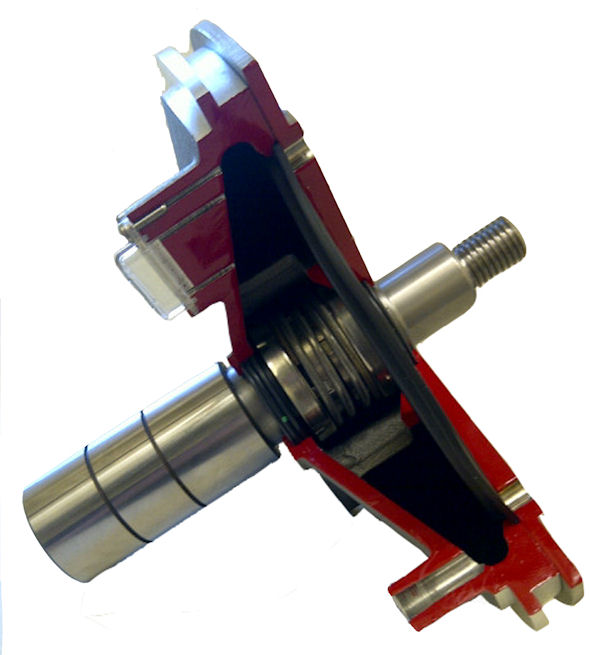

“A centrifugal pump like our Hypro 9307 is ideal for delivering fast flow rates, not only for quick tank filling but also for faster spraying speeds and high volume liquid fertiliser application,” he points out. “A positive displacement pump giving similar performance will likely be twice the price, a lot bigger and more complex – with eight pistons, 16 valves and numerous other components involved in routine servicing.”

In contrast, centrifugal pumps have few moving parts, resulting in excellent reliability and low maintenance requirement.

A new feature for the ‘contractor spec’ Hypro 9307 is an optional ‘wet’ seal that guards against the damage caused by inadvertently letting it run dry.

“A standard ceramic seal can fail if left to run dry for any length of time or if used with excessively abrasive liquids,” Roger James explains. “Pentair already offers a ‘Lifeguard’ silicon carbide seal that protects against such damage and provides up to 21 times longer service life, but the Hypro 9307 pump is the first available with the patented ‘Forcefield’ wet seal.”

This all but eliminates the risk of seal damage during typical run-dry situations, such as forgetting to shut off the sprayer pump on the journey from field to yard. It is therefore not only a high performance unit, with up to 1400 litre/min flow capacity, but also a practical choice for the main sprayer pump.

Roger James urges farmers to explore all options for the pump and induction system when buying a new sprayer, especially if they are keen to see quicker sprayer filling times.

“Quite rightly, farmers take time considering tank size, boom options and controls before buying a new sprayer,” he says. “But digging a bit deeper on pump and induction system pros, cons and performance will certainly help ensure they are getting the best set-up for fast sprayer re-filling turnarounds.”