The UK market leader in conveyor belting, Habasit Rossi, has become the first manufacturer to receive European Hygienic Engineering & Design Group (EHEDG) certification for one of its solutions.

EHEDG awarded the Certificate of Compliance to Habasit’s HyCLEAN plastic modular belts M5060 and M5065 with sprocket and Clean in Place (CIP) system.

The belts were evaluated by the Research Centre Weihenstephan for Brewing and Food Quality at the Technical University of Munich, Germany. This EHEDG authorised organisation awarded and published the Certificate of Compliance.

The award of this respected certificate to Habasit’s HyCLEAN products provides conclusive independent proof that it meets the highest standards of hygienic equipment design.

Ian Thornham, Sales and Marketing Director at Habasit Rossi, said: "The issue of creating and maintaining optimal hygiene conditions will always be at the top of the agenda for the food industry, which is why we continue to develop innovative solutions to help food plants to minimise cost and downtime."

"Hygienic design and ease of cleaning are crucial for equipment and components used in hygiene-sensitive food processes. Conveyor belts have an important role to play as they are often in direct contact with food."

"We’re pleased to have independent verification that the Habasit HyCLEAN CIP is a proven system to clean plastic modular belts - and others - thoroughly, efficiently and reliably."

Habasit Rossi launched HyCLEAN in 2009; it was specifically designed to meet the most demanding hygiene requirements, while delivering tangible cost savings and improvements to process and performance.

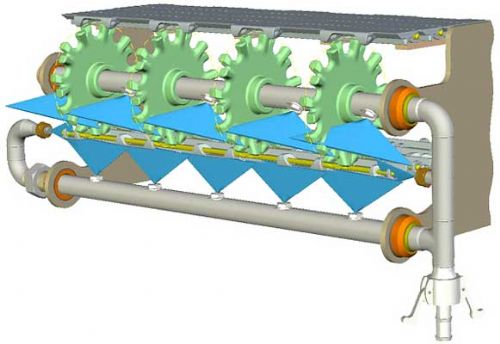

The HyCLEAN package includes a patented sprocket and a 2" flat top module, both made with an advanced, unique hygienic design.

The Habasit HyCLEAN CIP enables faster and more reliable cleaning cycles, and is adjustable to specific application dimensions and process set-ups. The system works even when water pressure is low by allowing the precise positioning of water jets, thus delivering substantial reductions in water use when compared with other CIP systems. In addition, it ensures less risk, as well as cost and time savings, compared with manual cleaning.